Air Hose Quick Connect Fittings

americanindustrialsupl and its partners may earn a commission if you purchase a product through one of our links.

Air hose quick connect fittings or airline couplers, available in a wide array of styles and formats, are versatile components found in numerous settings, from automotive to industrial and heavy-duty environments. These essential fittings streamline the process of connecting air hoses to pneumatic tools, such as impact wrenches, enhancing efficiency in workshops and factories alike.

FYPower 30 Pieces 1/4″ NPT Air Coupler and Plug Kit

Maximize Your Workshop’s Efficiency with FYPower’s Brass Quick Connect Set. The FYPower Air Coupler and Plug Kit, featuring a 1/4″NPT interface, offers a collection of 30 industrial-grade solid brass connectors, designed to make this task effortless.

Understanding the basics of air line fittings is crucial. These fittings comprise two main parts: the socket (female end) and the plug (male end), which when connected, ensure a secure and leak-free air flow. The variety in quick couplers’ shapes and styles does not compromise their fundamental purpose—to provide a reliable mechanical connection and a seamless air flow to power tools efficiently.

When selecting the right coupler for your needs, it’s important to consider three main factors: style, airflow, and connection type. The style, denoted by letters like ‘A’ and ‘G’, indicates the coupler’s air flow capacity, measured in cubic feet per minute (CFM). For instance, ‘A’ style couplers are suited for environments requiring lower air flow, such as auto body shops, while ‘G’ style couplers are designed for heavy-duty applications demanding higher airflow.

The Anatomy of Air Hose Quick Connect Fittings

Quick connect couplers, integral to the seamless operation of pneumatic tools, consist of two main components: the socket (female end) and the plug (male end). Typically, the socket is connected to the air hose, while the plug attaches to the pneumatic tool in use.

How Quick Couplers Work

Despite the variety in shapes and styles, the core functionality of pneumatic couplers remains consistent across all types. They securely hold the plug within the socket through a mechanical connection, ensuring a leak-free seal that allows air to flow uninterrupted. This connection might be achieved using various materials and designs, from metal bars to plastic latches or ball bearings. Each design, when correctly utilized, guarantees efficient and leak-free air flow to support your work. and helping you get the job done.

Components of Quick Connect Couplers

| Component | Description | Location |

|---|---|---|

| Socket | Female end, connects to air hose | Air Hose |

| Plug | Male end, connects to tool | Pneumatic Tool |

List of Common Materials and Designs for Mechanical Connection:

- Metal bars

- Plastic latches

- Ball bearings

Each material and design serves to provide a robust and reliable connection, essential for maintaining efficient workflow and minimizing downtime due to air leaks.

Categories of Couplers

If there are so many variations between manufacturers and styles and knowing the categories of couplers is essential when navigating the vast selection available on the market. These categories are broadly divided into style, airflow, and connection type.

Style:

Among the air hose quick connect fittings, you’ll encounter ten main styles, each marked with a unique letter to signify its profile. The ‘A’ and ‘G’ profiles stand out for their distinct airflow capacities, measured in standard cubic feet per minute (CFM). For instance, the ‘A’ style moves about 34 CFM, making it a go-to choice for auto body shops where tools require lower airflow. Conversely, the ‘G’ style facilitates up to 99 CFM, catering to the demands of heavy-duty mechanic shops needing higher airflow.

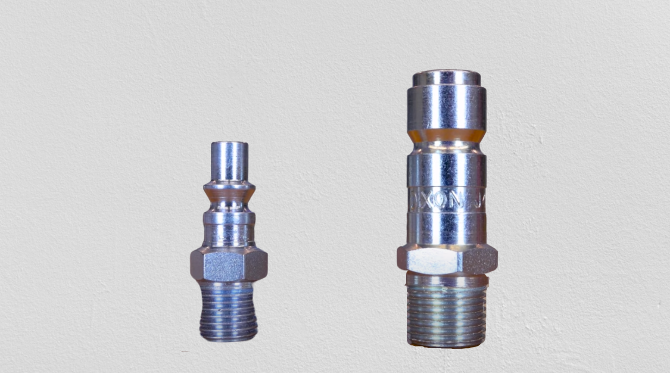

This is at the lower end of the scale and you would typically find this style of fitting in an auto body shop where the air tools generally need slower flow rates in order to function properly. At the other end of the scale you have the larger g style male coupler and/or plug. By looking at the profile first notice how different their profiles are you can tell already that this G style is going to pass more air through it, 99 CFMs to be precise.

You would need these guides on larger pneumatic tools that require a more substantial airflow to function, like in heavy duty mechanic shops. It is crucial that you match a couplers SCFM to the tool that you are using as too much air flow can break an air tool and too little air flow will not let the tool function properly.

Airflow Signs:

Airflow in couplers is categorized by basic flow sizes, which should not be confused with thread sizes. The flow size determines the air handling capacity, broken down as follows:

- Quarter inch couplers: Up to 40 SCFM

- 3/8 inch couplers: Up to 60 SCFM

- Half inch couplers: 60 SCFM and above

If you look at these two m style plugs in the image. We know that they can both output 40 s SCFM even though one has a 1/8 NPT connection and the other end has a 3/8 NPT connection. Even though one fitting can fit on a larger hose, both will output the same amount of air per minute because they are both classified as an M style coupler.

When we talk about the basic flow size it is very important to note we are NOT talking about the thread size of the connection on the air coupler. The basic flow size refers to the air handling capacity of the coupler. It breaks it down as follows quarter inch are couplers up to 40 SCFM, 3/8 are up to 60 SCFM and half inch are 60 SCFM and above. The thread size and the flow size are two measurements that are completely independent of each other. This means a larger thread size will not translate to a higher airflow because your airflow is determined by the design of the coupler.

Quick Connect Pneumatic Hose Fittings

Connection:

Not only can the connection on the end of the couplers be of different sizes but they can also be of different types too.

Connections vary in size and type, with the most common being female and male pipe connections (NPT) and hose barb connections. The key to efficient identification and use lies not in the manufacturer but in selecting the appropriate style for your application.

Identifying Styles

Each style’s unique profile aids in identification, with the male plug often serving as the starting point for comparison. Despite the similarities, careful examination of tip lengths and profiles is necessary to ensure compatibility.

Most manufacturers make as many styles as possible in order to a broad product offering. So, for example, you can have an M style plug made by Milton and an M style female coupler made by Errol and they will mate together perfectly as they are both the same style.

Unique Profiles

Each style has a unique profile, and this is what we use to identify them. If you look across all the major profiles you can see why air coupler identification can be so problematic without the correct knowledge.

You generally start with the male plug because if you compare a bunch of female couplers side-by-side it would be almost impossible to tell the styles apart. If you are fortunate you may find the identification of the plug stamped on to its side. If not, you will probably need to match by looking at a chart of types of quick coupler connections and find the style of the plug you have. On most charts you will also find the measurements for each plug.

Tip length is the length above the recessed groove where your female coupler would fix. Each style of coupler has their own unique measurement for this part. You need to be careful because some of them can be quite similar.

The Universal Socket

With air hose quick connect fittings simplicity and interchangeability is the main issue For those frequently working across multiple coupler profiles, a universal socket installed on your hose simplifies the process, allowing compatibility with almost every style of male plug.

.The universal socket is designed for those who work with multiple coupler profiles. Its clever design allows you to mate with almost every style of male plug there is.

FYPower 30 Pieces 1/4″ NPT Air Coupler and Plug Kit

Maximize Your Workshop’s Efficiency with FYPower’s Brass Quick Connect Set. The FYPower Air Coupler and Plug Kit, featuring a 1/4″NPT interface, offers a collection of 30 industrial-grade solid brass connectors, designed to make this task effortless.

Types of Quick Connect Couplers

Quick connect couplers come in a variety of designs, each tailored to meet the needs of different applications and pressure demands. Let’s explore the most common types in detail:

- Industrial Interchange Couplers: These are the go-to choice in fields like manufacturing, automotive, and construction. Their design allows for compatibility with a diverse range of tools and equipment, making them a versatile option in many workplace settings.

- Automotive Couplers: These are precisely engineered for use in automotive tasks. They feature a unique design that helps prevent them from being mistakenly connected with industrial interchange types, ensuring the right fit for automotive work.

- Aro Couplers: Often found in industrial environments, Aro couplers are recognized for their distinctive shape. They’re praised for their dependable performance, even when operating under a wide range of pressures, making

- European High Flow Couplers: These are designed to support applications that demand high air flow, such as specific manufacturing processes. They provide superior flow rates, which is essential for tasks requiring a substantial volume of air to be delivered efficiently and effectively.

Each of these types of quick connect pneumatic coupler has unique benefits tailored to specific operational needs across a range of professional settings.

Air Hose Quick Connect Fittings Colors and Materials

Air hose quick connect fittings can come in so many materials, colors and each with different features.

When purchasing quick connect fittings it is important to consider the working environment. For example, in indoor use cases hardened steel couplers are likely to be the best choice as they are less prone to damage when a hose is dropped or bashed against meta work surfaces or concrete floors.

In outdoor use cases brass couplers may be a better option to avoid the chance of rusting. I the hose is likely to get dragged around a lot then getting couplers with a drag guard feature is wise. This comes in useful as it will prevent your hose from catching on hazards on the ground and or accidentally disconnecting while moving around.

Colors

With regards to colors using them makes identification, even with a glance, much easier. Colored couplers are meant to match to avoid possibly mixing up dry and lubricated lines. What does that mean? Some tools use dry air lines and some use air lines with a small amount of oil in them to keep them internally lubricated. If you mixed up the hoses between dry and wet lines the performance of a tools will be adversely affected.

Choosing the Right Couplers

Selecting the appropriate quick connect couplers involves considering several factors:

- Working Environment: Choose hardened steel couplers for indoor environments to withstand wear and tear. For outdoor applications, brass couplers offer corrosion resistance.

- Material Types: The material of the coupler can affect its longevity and suitability for specific environments. Brass is ideal for resistance to corrosion, while stainless steel and hardened steel are better for high-pressure applications.

- Drag Guards for Hoses: Incorporate drag guards to protect the hose and coupler connection, especially in environments where the hose is moved frequently.

- Colored Couplers: Utilize colored couplers to prevent mix-ups between dry and wet lines, enhancing safety and efficiency in your workspace.

Considering the above points will help you choose pick the right couplers for your specific needs, allowing you to get optimal performance

Safety Considerations for Pneumatic Couplers

Ensuring safety when using pneumatic couplers involves understanding their pressure limitations and the importance of proper connections. Each coupler is designed to withstand specific pressure levels, and exceeding these can result in equipment failure or personal injury.

Always check the pressure rating of your couplers and ensure they meet or exceed the requirements of your pneumatic system. Additionally, securing a proper connection is crucial to prevent accidental disconnections or leaks, which could lead to sudden hose whip. Regular inspection and maintenance of couplers and connections help in identifying potential issues before they lead to accidents, ensuring a safe working environment.

For more details on regulations’ and standards, see the article for safe use of quick connect couplers.

Troubleshooting Common Issues

When working with quick connect couplers, encountering leaks can be frustrating. Here are some strategies to address and prevent these issues:

- Ensure Proper Connection: Verify that the coupler and plug are securely connected. A loose fit can lead to air leaks.

- Match Styles Correctly: Using mismatched styles can cause leaks. Ensure both the coupler and plug share the same profile.

- Regular Inspection: Routinely check for wear and tear on both the socket and plug. Check both the coupler and plug replacing any components showing signs of damage or excessive wear and tear.

- Use the Right Size: Ensure the coupler and plug sizes are compatible. Incorrect sizes can lead to poor connections and leaks.

- Check Seals and O-Rings: Worn or damaged seals can cause leaks. Inspect and replace O-rings or seals as needed. Applying PTFE tape on the threads can help seal connections and prevent air from escaping.

- Tighten Connections: Use appropriate tools to tighten connections without over-tightening, which can damage threads.

These step should minimize the occurrence of leaks and allow you to maintain a reliable and efficient pneumatic system.

Quick Connect Pneumatic Hose Fittings

FAQ: Air Hose Quick Connect Fittings

What factors should I consider when selecting air hose quick connect fittings for high-pressure environments? For high-pressure environments, consider fittings’ material strength (opt for hardened steel or stainless steel for durability), the maximum pressure rating (ensure it exceeds your system’s requirements), and compatibility with your hose and tools to prevent leaks or disconnections.

How can incompatibility of air hose quick connect fittings affect the performance of the system? Incompatibility can lead to air leaks, reduced efficiency, and even damage to tools and equipment. It’s crucial to match the fittings’ style, size, and material to your system’s requirements to ensure optimal performance and safety.

What are the main safety considerations when using pneumatic couplers? Ensure couplers match the system’s pressure requirements, regularly inspect for wear and damage, and use the correct type and size to prevent accidental disconnections. Additionally, understanding the airflow requirements of your tools can prevent overpressure situations that might lead to equipment failure or injury.

I’ve been involved in the welding industry for over twenty years. I trained in various engineering shops working on various projects from small fabrication and repairs through to industrial projects.I specialize in welding aluminum and food grade stainless steel and an now run an engineering shop fabricating equipment for the food industry.