Laser Welding: What You Need To Know

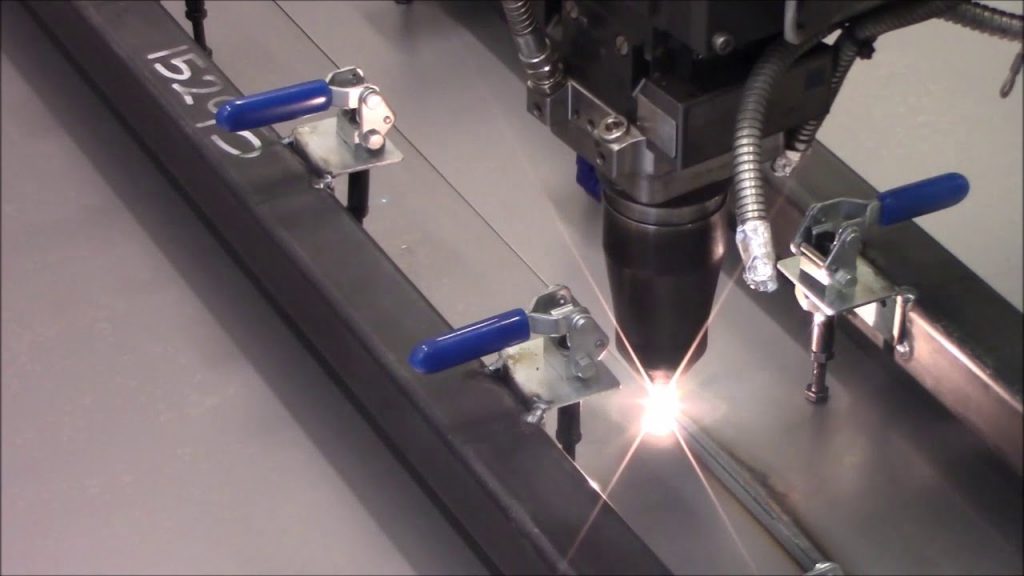

Laser welding, or more commonly refereed to as laser beam welding is an industrial welding process for joining metal components together at high speed. It usually produces small and very narrow weld seams and the process has low thermal distortion. This type of welding lends itself well to large scale production lines were the ability to combine fast welds, an automatic process and quality to be controlled online. Because of this laser welding is used widely used, where it is feasible, in the modern industrial production process.

Laser Welding Equipment

The Lasers welding equipment that is used in today’s industry exist in two forms; Gas and Solid State Lasers. Most Gas Lasers use carbon dioxide gas and Solid State Lasers use a Nd:YAG Laser.

Laser Welding Equipment – Solid State Lasers

The solid state laser is comprised of several materials these include:

- Chromium in aluminum oxide

- Synthetic ruby

- Crystal made of yttrium aluminum (Nd:YAG) or neodymium

- Neodymium in glass (Nd:glass)

A solid state laser operates on a wavelength of 1 micrometer. This is much shorter wavelength than the wavelength of gas lasers. Because of this fact, welder operatives, who use such laser equipment are required to wear special protective eye wear or use special screens. The reason for this is to prevent possible retina damage to their eyes. Solid state lasers can operate in a continuous mode as well as a pulsating mode.

The original design of this laser is still widely used. It consists of a single crystal rod that is 200mm in length and 20mm in diameter, both ends of the crystal are ground flat. The rod is enclosed in a flash tube filled with Krypton and Xenon and when the tube is flashed with light, a laser beam is emitted (it lasts about 2 milliseconds per flash).

Disk shaped crystals are now becoming popular in the laser industry and diodes are replacing flash lamps to provide a greater efficiency. Fiber optics are now used to deliver the high intensity beam to the welding area

Laser Welding Equipment – Gas Lasers

Gas lasers are composed of a mixture of gases that include nitrogen, carbon dioxide (CO2) and helium

Gas lasers require a low current from high voltage power source to provide the energy that is needed to excite the mixture of gases that are used for the lasing medium. Gas lasers can operate in both a pulsating or continuous fashion. The laser beam has a wavelength of 10.6 micrometers. Fiber optics are destroyed at this wavelength so a strong lens and mirror is used to deliver the beam to the weld. The power output of the gas laser is much higher than a solid state laser and can reach 25 kW.Laser.

Fiber Lasers incorporate technology that uses an active gain medium such as an optical fiber that is doped with rare earth metals including Thulium, Praseodymium, Neodymium, Ytterbium, and Erbium. These materials will amplify light without lasing and are related to doped fiber amplifiers. Another media that can be used for fiber lasers is Fiber non-linearities such as four-wave mixing or Raman scattering.

Laser Welding: Safety

There are several important safety issues to keep in mind when using laser welding equipment.

Eye Exposure to certain laser light wavelengths and power can cause retinal or corneal burns and in extreme cases both. Excessive exposure will cause retinal injury.

Extensive skin exposure to optical radiation may burn the skin. Exposure to certain wavelengths (290320 nm) may lead to skin cancer.

In order for some lasers to work hazardous chemicals need to be introduced to the welding process care must be taken by the operative to ensure his or her safety.

An electrical high voltage is required for most lasers and precaution against fire risk is essential:

There is always risk of fire whether it is caused by the dyes used in the welding process or the high voltage of the power that is required to operate the equipment.

It is important to remember that the beams from the laser can also ignite flammable materials in the vicinity of the operation where the work is being conducted.

Buying Equipment

Before you purchase any laser welding equipment you must make sure that you know exactly which type of equipment you will require for your welding projects. You do not want to buy a laser welding system that does not do the job.

I’ve been involved in the welding industry for over twenty years. I trained in various engineering shops working on various projects from small fabrication and repairs through to industrial projects.I specialize in welding aluminum and food grade stainless steel and an now run an engineering shop fabricating equipment for the food industry.