Compare TIG Welding Ignition Methods: Scratch vs Lift vs High-Frequency Start TIG

americanindustrialsupl and its partners may earn a commission if you purchase a product through one of our links.

When you’re aiming for clean and successful welds, the way you initiate the arc plays an important role. In TIG welding (Gas tungsten arc welding –GTAW), getting off to the right start isn’t just about skill; it’s about choosing the right technique for the job. Today, we will compare tig welding ignition methods: scratch vs lift vs high-frequency start

Among the various methods of ignition available, the three main ones are: scratch start, lift start, and high-frequency start. Each of these ignition methods comes with its own set of advantages and challenges. Knowing the differences is key to selecting the method that best suits your welding needs, ensuring a smooth and efficient welding process from the get-go. Below we will briefly look at each of these techniques to shed light on their processes, benefits, and limitations.

Scratch Start

The scratch start method is akin to striking a match. You initiate the arc by lightly touching the tungsten electrode to the work surface and then quickly pulling it away. This action sparks the arc needed for welding. While straightforward, this technique mirrors lighting a fire with flint; it’s basic yet requires a deft touch.

One of the main drawbacks of scratch start is the risk of contaminating the tungsten electrode. If the electrode sticks to the metal, bits of material can adhere to it, potentially compromising the weld’s quality. Additionally, achieving precise control over arc initiation can be challenging. It’s like trying to light a delicate candle with a large torch; precision is key, but the tool isn’t always cooperative.

Despite these challenges, scratch start remains popular, especially in environments where simplicity and equipment availability dictate technique choice. It’s a testament to the welder’s skill, allowing for effective welding with minimal setup, though it demands a steady hand and careful technique to minimize its inherent drawbacks.

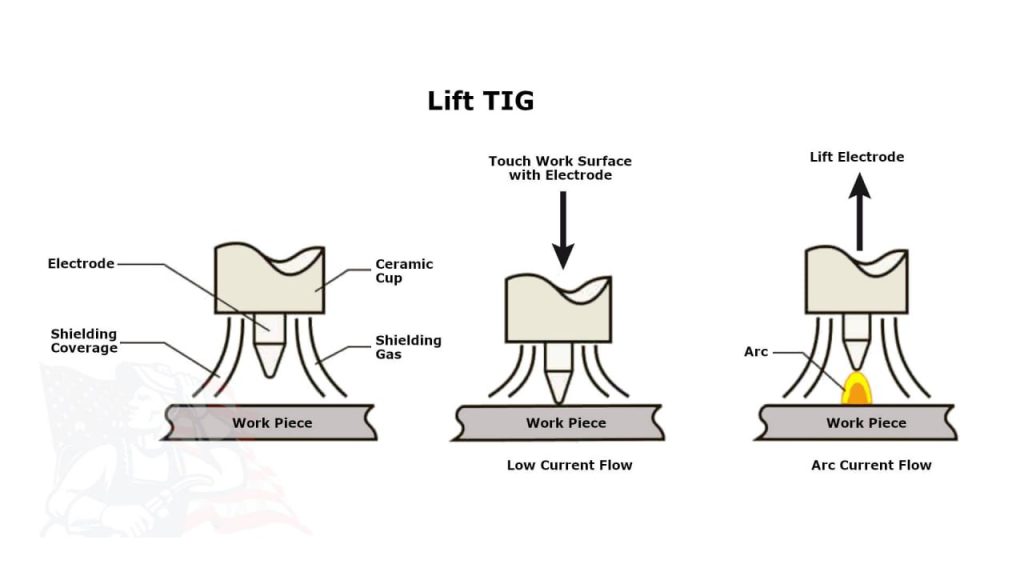

Lift Start

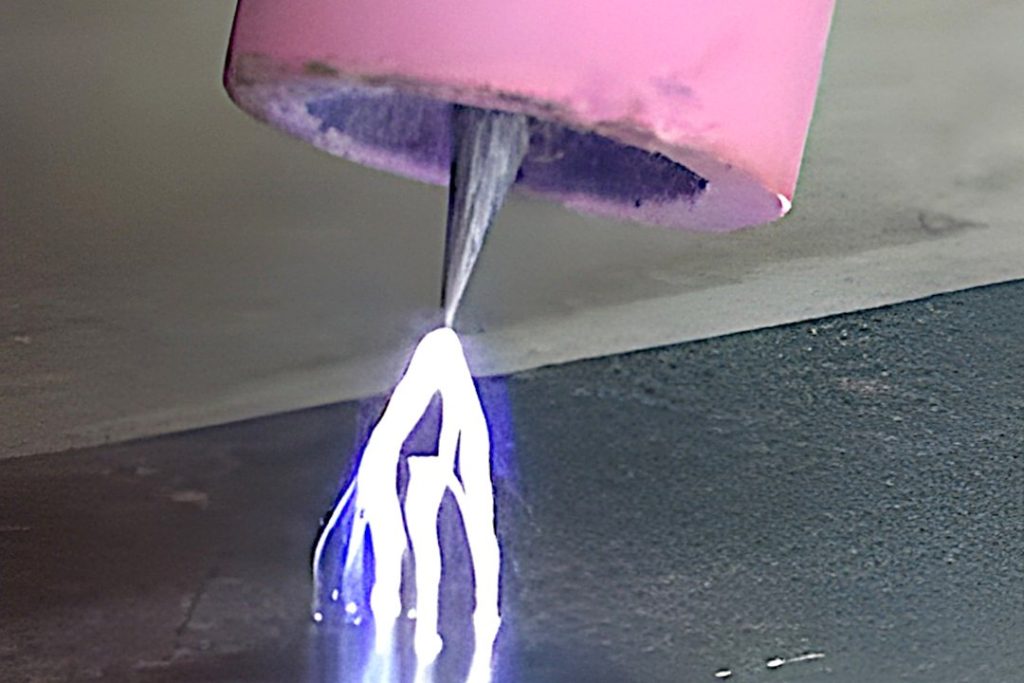

Lift start takes a more refined approach to initiating the arc. In this method, the welder touches the tungsten electrode to the workpiece and then activates a foot pedal, which signals the welder to lift the torch. This action creates a smooth arc with minimal contact between the electrode and the workpiece. Think of it as using a remote control to gently wake a device from sleep mode; it’s controlled and precise.

This technique offers a significant advantage over scratch start by reducing the likelihood of tungsten contamination. Since the electrode barely touches the workpiece, the chances of material transfer are much lower, akin to tapping a drum lightly to produce a sound without leaving a mark. Furthermore, lift start affords the welder greater control over the arc initiation, making it easier to manage and predict. It’s comparable to starting a car with a key fob rather than a traditional key, providing a smoother and more reliable experience.

For those seeking cleaner welds and more control without the higher costs associated with advanced methods, lift start is an excellent middle ground. It bridges the gap between the simplicity of scratch start and the sophistication of high-frequency start, offering a balanced option for welders aiming to enhance their welding quality with manageable technology..

High-Frequency Start

High-frequency start represents the pinnacle of TIG welding ignition techniques. This method doesn’t require the tungsten electrode to make physical contact with the workpiece. Instead, a high-voltage, low-current spark ionizes the gas between the electrode and the metal, allowing the arc to start without direct contact. It’s akin to using a sophisticated electronic device that turns on with just a gesture, avoiding the need for physical touch.

The major benefit of this approach is the significant reduction in tungsten contamination. Since the electrode never touches the workpiece, the risk of material transfer is virtually eliminated. This is comparable to using a laser pointer to guide someone’s gaze without having to point directly with your finger, ensuring precision without contact.

Moreover, high-frequency start enables precise arc initiation, making it ideal for welding sensitive materials like aluminum, which require a clean, controlled start to prevent weld defects. It offers welders the capability to initiate the arc exactly where they intend, much like a surgeon using a laser for precise incisions.

This method is particularly favored for its ability to produce superior welds on a variety of materials, offering unparalleled control and cleanliness. However, it comes at a cost, requiring more sophisticated, and therefore expensive, equipment. For professionals and those committed to achieving the highest quality in their work, the investment in high-frequency start technology is often considered worthwhile, setting the standard for excellence in TIG welding.

Compare TIG Welding Ignition Methods: Scratch vs Lift vs High-Frequency Start

The following detailed table outlines the key differences among scratch start, lift start, and high-frequency TIG welding techniques. This table includes additional information to provide a comprehensive comparison.

| Feature | Scratch Start TIG Welding | Lift Start TIG Welding | High-Frequency TIG Welding |

|---|---|---|---|

| Arc Initiation | Manually scratching the tungsten electrode across the surface. | Touching the electrode to the workpiece then lifting off. | High-frequency current initiates the arc without contact. |

| Ease of Use | Requires skill to avoid contaminating the electrode or the workpiece. | More user-friendly than scratch start, with less risk of contamination. | Easiest to use; no contact needed for arc initiation. |

| Suitability | Suited for environments where electronic interference is not a concern. | Versatile, used in various settings without electronic interference issues. | Ideal for a wide range of materials and environments, especially sensitive electronic applications. |

| Risk of Contamination | Higher, due to electrode contact with the workpiece. | Reduced, but still present due to initial contact. | Minimal, as there is no contact between the electrode and the workpiece. |

| Material Compatibility | Effective for steel and stainless steel. | Good for most metals, including steel and aluminum. | Excellent for a broad array of materials, including carbon steels, stainless steels, nickel alloys, aluminum and its alloys, copper and its alloys, titanium, magnesium, and more. |

| Preferred Techniques | Basic, requires manual dexterity. | Can be used with a variety of welding techniques. | Allows for advanced techniques like forehand or push welding, backhand welding, and modulated TIG arc. |

| Equipment Complexity | Minimal, basic TIG setup required. | Moderate, with some mechanisms to facilitate lift start. | High, requires sophisticated equipment capable of generating high-frequency current. |

| Cost | Generally lower due to simpler equipment. | Moderate, with additional costs for lift-start capability. | Higher, due to the advanced technology and equipment involved. |

The table shows that while scratch start and lift start are more manual and require direct contact with the workpiece, high-frequency TIG welding offers a superior, contactless experience. High-frequency TIG welding stands out for its ease of use, minimal risk of contamination, and versatility across a wide range of materials.

Variations In Safety Precautions

Next is a table outlining the differences in precautions needed for scratch start, lift arc, and high-frequency TIG welding techniques, along with additional insights to ensure a comprehensive understanding.

| Precaution Category | Scratch Start | Lift Arc | High Frequency |

|---|---|---|---|

| Arc Initiation | Risk of electrode contamination and damage. | Lower risk of electrode sticking and damage. | No contact, but requires careful handling due to high-frequency emissions. |

| Equipment Handling | Requires skill to avoid sticking the electrode. | Requires good control but less skill than scratch start. | Requires understanding of equipment settings to manage high-frequency spark. |

| Safety Gear | Standard TIG welding gear: gloves, helmet, protective clothing. | Same as scratch start, with emphasis on precision handling. | Same, but with additional precautions for electromagnetic interference (EMI) protection if necessary. |

| Electrode Contamination | High risk, leading to potential weld defects. | Reduced risk due to controlled arc start. | Minimal risk, promoting cleaner welds. |

| Electronic Interference | Minimal concern. | Minimal concern. | High; requires measures to prevent interference with nearby electronics. |

| Health and Safety | Standard welding precautions apply. | Same as scratch start, with focus on reducing accidental contact. | Increased focus on avoiding exposure to high-frequency emissions; may require additional ventilation or shielding in sensitive environments. |

| Environmental Considerations | Adequate ventilation to remove fumes. | Similar to scratch start, ensuring clean air. | Same, with added caution for environments with sensitive electronics or medical equipment. |

| Weld Quality | Potentially lower due to contamination. | Generally higher with cleaner starts. | Highest, with precise control and reduced contamination. |

| Cost and Complexity | Lowest, with basic setup. | Moderate, requires specific equipment features. | Highest, due to advanced technology and potential need for EMI mitigation strategies. |

It is clear that there are unique precautions that should be taken and considerations associated with each TIG welding technique.

It highlights that while scratch start may pose risks of contamination and requires significant skill, lift arc offers a balance between ease of use and quality. High-frequency welding, despite its complexity and cost, provides the highest quality welds with the least risk of contamination, but necessitates stringent precautions against electromagnetic interference and health hazards.1

Proper safety gear, awareness of environmental considerations, and equipment handling are essential across all methods to ensure optimal outcomes and safety.

TIG Methods What Real Welders have to Say:

I recently had the chance to have a coffee and skype chat with a couple of collogues, Jerry Babcock and Phil Yates, that I have welded with through my career during which we had the opportunity to chat about the different TIG methods:

Me (Tommy): “Well, let’s dive right in. I’ve been stickin’ to scratch start for most of my projects recently. You gotta be alert, but once you’ve got it, it’s smooth sailing. Used it on a custom bike frame last month. The simplicity? Can’t beat it.”

Jerry: “Scratch start’s great for getting down to business quick. But down here in Dallas, lift start’s been my go-to, especially with those finicky art installations. Gives me that gentle touch, like easing into a slow dance. Plus, the control is as sweet—keeps the tungsten cleaner, too.”

Phil: “Both solid techniques, lads. But for me, high-frequency start’s the bee’s knees. Worked on this intricate aluminum sculpture for a client in Kensington. The precision? Like threading a needle with your eyes closed. No touching, no fuss.”

Me: “Ain’t it a bit overkill for simpler jobs, though? I mean, New York’s fast, but even we know when to keep things straightforward.”

Phil: ” It’s about the right match for the job at hand. London’s eclectic projects have shown me the value of adaptability. High-frequency start might be a bit much for everyday projects, but when you need that precision, it’s unbeatable.”

Jerry: “Still think Tommy’s got a point, Phil. Not every weld needs a show pony. But I reckon it’s all about having the right tool for the job. For me I usually prefer the finesse lift start brings to the table.”

Me: “Had this vintage car restoration last spring, right? Body was a mess, needed a touch that only scratch start could give. Requires precision, but once you’re in the groove with scratch, it’s smooth. That bike frame I mentioned? Came out so slick, it was like the metal and I were old friends catching up.”

Phil: But this high-frequency start project I had? A client wanted a custom aluminum frame for an abstract art piece, The level of detail required was right up there. High-frequency let me move around the metal without actually touching it, Ended up so delicate, it was as if the metal had come to life.”

Jerry: “It’s all about the right tool and the right touch. Whether it’s the rugged charm of scratch start, the refined grace of lift start, or the precision of high-frequency, we’re all just trying to make the best and structurally sound welds that we can.

Me: “Well, it’s clear we’ve all found our rhythm with our TIG set ups. Whether it’s the straightforward charm of scratch start, the gentle nuance of lift start, or the high-tech precision of high-frequency, it’s about making the torch sing the right note for the job at hand,”

The good news is that both Jerry and Phil are going to start to write for the site soon so that you can benefit from the combined wealth of our welding careers.

Wrapping Up: Scratch Start vs. Lift Start vs. High-Frequency

The choice of arc initiation method is more than just a technical decision when welding TIG; it’s a reflection of the welder’s approach to their craft. As we’ve seen through my experiences and those of Jerry, and Phil, each method—scratch start, lift start, and high-frequency start—carries its own set of benefits and challenges.

Scratch start, with its straightforward simplicity, appeals to those who value a no-frills approach. Lift start, offering a balance between ease of use and control, is perfect for projects that require a delicate touch. High-frequency start, the pinnacle of precision, is the choice for welders working on sensitive materials or intricate designs.

The conversation I had with Phil and Jerry underscores a crucial point: the best method is the one that aligns with your project needs, skill level, and the unique demands of the material you’re working with. It encourages us to consider not just the technical aspects of each method, but also the artistry and adaptability required in welding.

The choice of arc initiation method be guided by the requirements of your work and your personal style as a welder. Whether you’re in the heart of a bustling city, the vastness of the countryside, or anywhere in between, the right approach will help you achieve welds that are not only structurally sound but also aesthetically pleasing.

Notes

I’ve been involved in the welding industry for over twenty years. I trained in various engineering shops working on various projects from small fabrication and repairs through to industrial projects.I specialize in welding aluminum and food grade stainless steel and an now run an engineering shop fabricating equipment for the food industry.