A Comprehensive Guide to E71T-1C Flux Core Wire

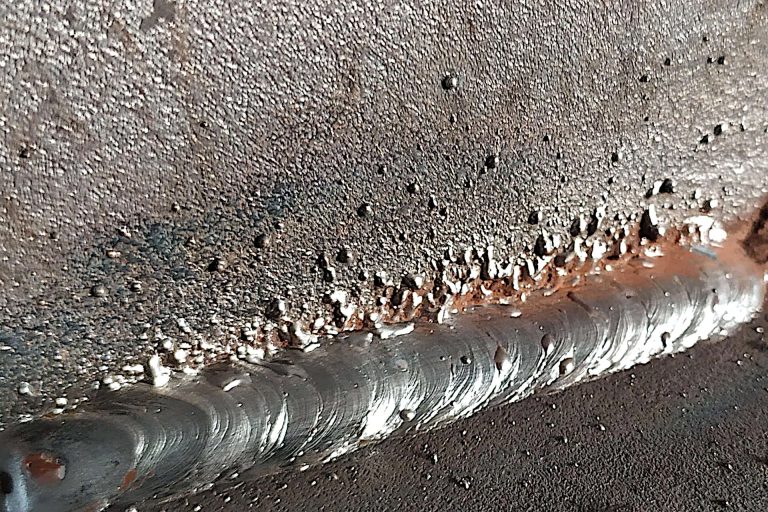

E71T-1C flux core wire is a type of welding consumable that consists of a metal tube filled with flux, which provides shielding and deoxidizing agents during the welding process. Flux core wire can be used for welding low-alloy and carbon steel in various applications, such as structural steel fabrication, shipbuilding, offshore construction, and heavy equipment…