Using a Gas Lens for TIG Welding Applications

americanindustrialsupl and its partners may earn a commission if you purchase a product through one of our links.

Tungsten Inert Gas (TIG) welding is a popular process requiring a lot of skill and expertise. It is commonly used to weld thin sections of stainless steel, aluminum, and other non-ferrous metals.

One often underused aspect of TIG welding is the use of a gas lens, which can play a crucial role in enhancing the weld quality and improving the overall welding process.

The ere are several factors that will determine when how and where you would utilize the use of a gas lens. Below, we will explore how to use it for properly, what its main applications are for, and when it is not suitable to use. We will also discuss whether gas lenses save gas and how it compares or whether they can be used as an alternative to Gasless TIG welding.

What Exactly is a Gas Lens for TIG Welders:

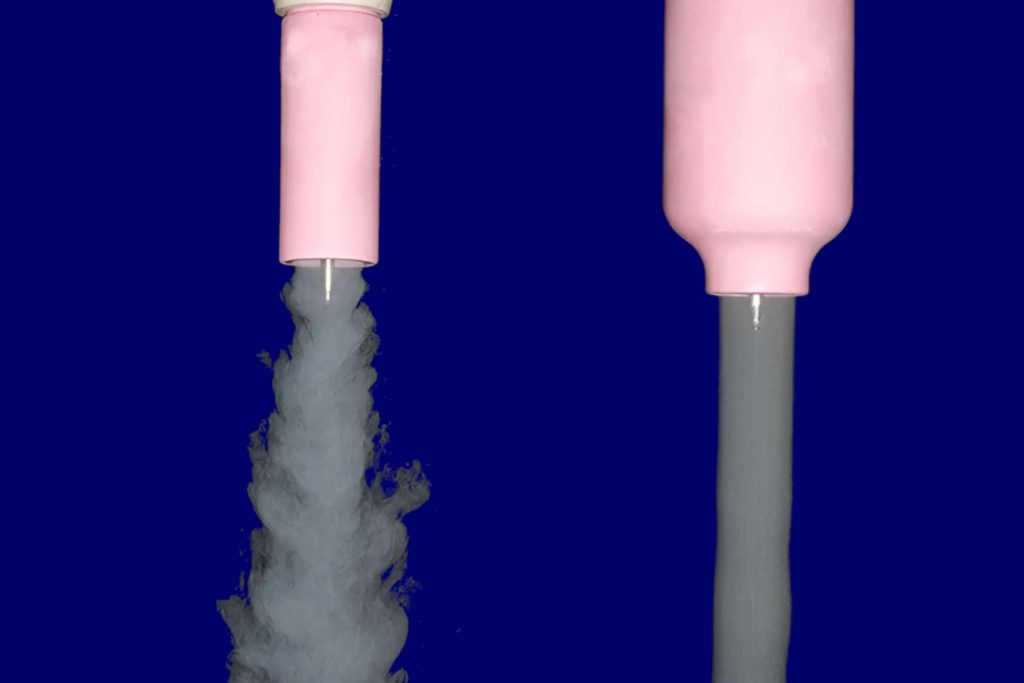

A gas lens is a component of the TIG welding torch that is inserted between the collet and the nozzle. It is a type of diffuser that helps to distribute the shielding gas evenly around the weld area, creating a stable and consistent shielding environment.

The gas lens consists of a series of screens that are designed to straighten and distribute the gas flow evenly around the tungsten electrode, allowing for better gas coverage and weld quality.

The gas lens also helps to reduce turbulence and turbulence-induced weld defects, such as porosity and contamination. By using a gas lens, welders can achieve better gas coverage, improved weld quality, and reduced weld defects, making it an essential component of the TIG welding process.

How to use a Gas Lens for TIG Welding:

Using a gas lens for TIG welding is a straightforward process that requires minimal setup. Here are the steps involved in using a gas lens for TIG welding:

- Insert the gas lens into the collet body: Remove the collet from the torch and insert the gas lens into the collet body. Ensure that the gas lens is inserted correctly and securely.

- Reassemble the collet: Reassemble the collet and ensure that it is tightened properly.

- Insert the tungsten electrode: Insert the tungsten electrode into the collet and ensure that it is tightened properly.

- Adjust the nozzle: Slide the nozzle onto the collet and adjust it to the desired length.

- Turn on the gas flow: Turn on the gas flow to the desired level and adjust the flow rate as required.

- Start welding: With the gas lens in place, start welding as usual. The gas lens will help to distribute the shielding gas evenly around the weld area, creating a stable and consistent shielding environment.

By following these simple steps, welders can easily use a gas lens for TIG welding and achieve improved weld quality and reduced weld defects.

Do Gas Lenses Save Gas?

Yes, gas lenses can save gas when used properly. The gas lens helps to distribute the shielding gas evenly around the weld area, creating a stable and consistent shielding environment. This means that less gas is required to achieve the same level of coverage compared to using a standard TIG welding setup without a gas lens.

The even gas distribution also reduces the amount of gas that is wasted, as there is less turbulence and turbulence-induced gas loss. Additionally, the gas lens helps to reduce the amount of gas that is blown away from the weld area by the welding arc, which can also result in gas savings.

However, it is important to note that the actual amount of gas saved may vary depending on the specific welding application and the gas flow rate used. It is essential to optimize gas flow rates based on the particular application and weld type to achieve the best gas savings.

Occasions When a Gas Lens Can Use More Gas

While gas lenses are designed to improve gas coverage and reduce turbulence, they still require a steady flow of gas to function effectively.

In situations where gas supply is limited in the first place, using a gas lens may actually lead to increased gas consumption to ensure steady flow. In these situations, it may be better to use a standard gas cup or nozzle, which can provide adequate gas coverage with less gas consumption. So, while gas lenses do save gas compared to a standard cup, they still require a certain level of gas flow to function effectively.

Overall, gas lenses can help to reduce gas usage, which is an important factor to consider, especially when working with expensive or scarce gases like helium.

Is it an alternative to Gasless TIG welding

No, using a gas lens for TIG welding is not an alternative to gasless TIG welding, also known as TIG flux corded welding. Gasless TIG welding uses a flux-cored tungsten electrode that is designed to create a shielding gas through the action of the arc. This eliminates the need for an external shielding gas and can be useful in outdoor welding applications where wind can blow away the gas.

On the other hand, using a gas lens with a TIG welding setup requires the use of an external shielding gas, typically argon or a mixture of argon and helium. The gas lens helps to improve gas coverage and distribution, which leads to better weld quality and reduced weld defects, as mentioned earlier.

While both gasless TIG welding and TIG welding with a gas lens are used to achieve high-quality welds, they are two distinct processes that cannot be used interchangeably. The choice between gasless TIG welding and TIG welding with a gas lens ultimately depends on the specific welding application and the welder’s preference.

What are the main applications where you would use a Gas Lens?

Gas lenses are commonly used in TIG welding applications that require high-quality welds with minimal defects. Here are some of the main applications where a gas lens can be used:

- Aerospace and aviation: TIG welding is commonly used in the aerospace industry for its precision and quality. Gas lenses help to improve gas coverage and distribution, which is critical for welding thin materials and complex shapes used in aircraft and aerospace components.

- Automotive: Gas lenses are used in TIG welding applications for automotive repairs and customizations, such as exhaust systems, roll cages, and suspension components. The even gas coverage provided by a gas lens helps to reduce weld defects and ensure high-quality welds.

- Medical devices: TIG welding is often used in the manufacture of medical devices due to its precise and clean welding capabilities. Gas lenses help to maintain a stable and consistent shielding environment, which is essential for welding small and delicate medical components.

- Food and beverage industry: TIG welding is used in the food and beverage industry to create high-quality and sanitary welds on stainless steel equipment, such as tanks, pipes, and valves. Gas lenses help to prevent weld defects and ensure a smooth, clean weld surface that is easy to clean and sanitize.

- Fabrication and construction: Gas lenses are also used in TIG welding applications for fabrication and construction, such as welding stainless steel handrails, gates, and fences. The improved gas coverage and distribution provided by a gas lens can help to reduce weld defects and ensure a clean, smooth weld surface.

Overall, gas lenses are useful in any TIG welding application where high-quality welds are required, and weld defects must be minimized.

On what applications or when would you not use a Gas Lens?

While gas lenses are useful in many TIG welding applications, there are some situations where they may not be necessary or appropriate. Here are some examples:

- Heavy-duty applications: In some heavy-duty TIG welding applications, such as welding thick materials or large structures, gas lenses may not be necessary. The increased gas flow required in these applications may be better served by a larger gas cup or nozzle, which can provide the necessary gas coverage and distribution.

- Short welds: For short welds, gas lenses may not be necessary, as the time required for the gas flow to stabilize and provide full coverage may exceed the length of the weld. In these cases, a standard gas cup or nozzle may be sufficient.

- Welding in tight spaces: When welding in tight spaces or with complex shapes, a gas lens may not be practical or even possible to use. In these situations, a standard gas cup or nozzle may be the only option.

- Limited gas supply: In situations where gas supply is limited, such as when welding in remote locations or using portable welding equipment, using a gas lens may not be practical due to the increased gas consumption.

Summary

Although gas lenses are useful in many TIG welding applications, they may not be necessary or appropriate in all situations. It is essential to consider the specific requirements of the welding project and determine the most suitable gas cup or nozzle for the job.

A gas lens can provide many benefits, including improved gas coverage, reduced turbulence, and increased arc stability. By providing a focused and consistent stream of gas, a gas lens can help ensure high-quality welds and reduce the risk of defects and contamination. However, it is essential to consider the specific requirements of each welding project and determine whether a gas lens is necessary or appropriate.

While gas lenses can be highly beneficial in many applications, they may not be necessary or practical in all situations. Ultimately, by carefully assessing the welding project and selecting the appropriate equipment, TIG welders can achieve the best possible results and ensure the highest level of quality and safety.

Further Reading:

- The IJES: N.Jeyaprakash, Adisu Haile, M.Arunprasath: The parameters and equipment used in TIG welding: A review

- ScienceDirect: Alcindo F. Moreira: An Initial Investigation of Tungsten Inert Gas (TIG) Torch as Heat Source for Additive Manufacturing (AM) Process

I’ve been involved in the welding industry for over twenty years. I trained in various engineering shops working on various projects from small fabrication and repairs through to industrial projects.I specialize in welding aluminum and food grade stainless steel and an now run an engineering shop fabricating equipment for the food industry.