Welding – Metal Fabrication through Fusion

Welding metal fabrication through fusion and is a crucial part of the manufacturing process. Welding is often used in construction, shipbuilding, vehicle fabrication, pipe fitting, machine building, aircraft manufacture, and many other fields.

American Industrial supplies will bring you all the best information on the newest welding products We have been providing quality reviews and advice on welding equipment for over ten years.

We will provide you with practical tutorials to help you learn how to weld as well as current best practices and health and safety regulations as well as keep you up to date with the latest courses and educational programs available.

MIG Welding

-

Does Flux Core Welding Require Gas?

A common question often asked by new welders is new welders have questions about whether or not it requires a shielding gas. The short answer is – it depends! Flux core welding refers to a process that uses a wire electrode filled with flux. This flux protects the weld from contamination during welding. However, there are two main…

-

Flux Core Wire for Welding Aluminum – Exploding the Myth

In simple terms you can’t use flux core welding method with aluminum so flux core wire for welding aluminum doesn’t exist and you will waste a lot of effort trying to find or weld aluminum using the flux core method. It is easy to see why this myth perpetuates. The flux core method holds a…

-

The Ultimate Guide to Selecting the Best Flux Core Wire

The selection of the most best flux core wire for welding projects is crucial, as it directly impacts the quality and durability of welds. When picking the most suitable flux core wire for a job various factors should impact your decision, including the materials being welded, the welding use case, wire diameter, flux type, shielding…

-

Weld Galvanized Steel with Flux-Cored Wire

Welding galvanized steel with flux core wire can be challenging especially if you are not familiar with the flux core method. Galvanized steel is coated with a layer of zinc that protects it from corrosion, but also creates problems when welding. The zinc can vaporize and form toxic fumes, which can cause health issues and…

-

What Are the Differences Between MIG Welding versus Flux- Cored Arc Welding

Flux-Core and MIG welding are two of the most commonly used welding techniques. Flux-Core welding uses a continuously-fed consumable electrode, which is shielded by a flux compound to protect the weld area from atmospheric contamination. MIG welding, on the other hand, uses a continuously-fed consumable wire electrode and a shielding gas to protect the weld…

-

How to MIG Weld Without Gas (Flux Core MIG Welding)

Whether you’re a homeowner trying to repair your roof or a professional steelworker trying to get your job done there are going to be times when you might need to weld without using gas. There are various different ways of welding with the use if a shielding gas and each has its own drawbacks. Generally…

TIG Welding

-

Compare TIG Welding Ignition Methods: Scratch vs Lift vs High-Frequency Start TIG

When you’re aiming for clean and successful welds, the way you initiate the arc plays an important role. In TIG welding (Gas tungsten arc welding –GTAW), getting off to the right start isn’t just about skill; it’s about choosing the right technique for the job. Today, we will compare tig welding ignition methods: scratch vs lift…

-

Flux Core Wire for Welding Aluminum – Exploding the Myth

In simple terms you can’t use flux core welding method with aluminum so flux core wire for welding aluminum doesn’t exist and you will waste a lot of effort trying to find or weld aluminum using the flux core method. It is easy to see why this myth perpetuates. The flux core method holds a…

-

Technique de Soudage: Soudure TIG ou MIG

Le soudage est une technique essentielle dans la transformation de métal, permettant l’assemblage de pièces qui seraient autrement impossibles à créer. Le soudage consiste à chauffer les métaux afin de les fusionner et donc de créer une jointure permanente entre eux. Ce processus implique plusieurs éléments tels que la source de chaleur (arc électrique, flamme,…

ARC Welding

-

Compare TIG Welding Ignition Methods: Scratch vs Lift vs High-Frequency Start TIG

When you’re aiming for clean and successful welds, the way you initiate the arc plays an important role. In TIG welding (Gas tungsten arc welding –GTAW), getting off to the right start isn’t just about skill; it’s about choosing the right technique for the job. Today, we will compare tig welding ignition methods: scratch vs lift…

-

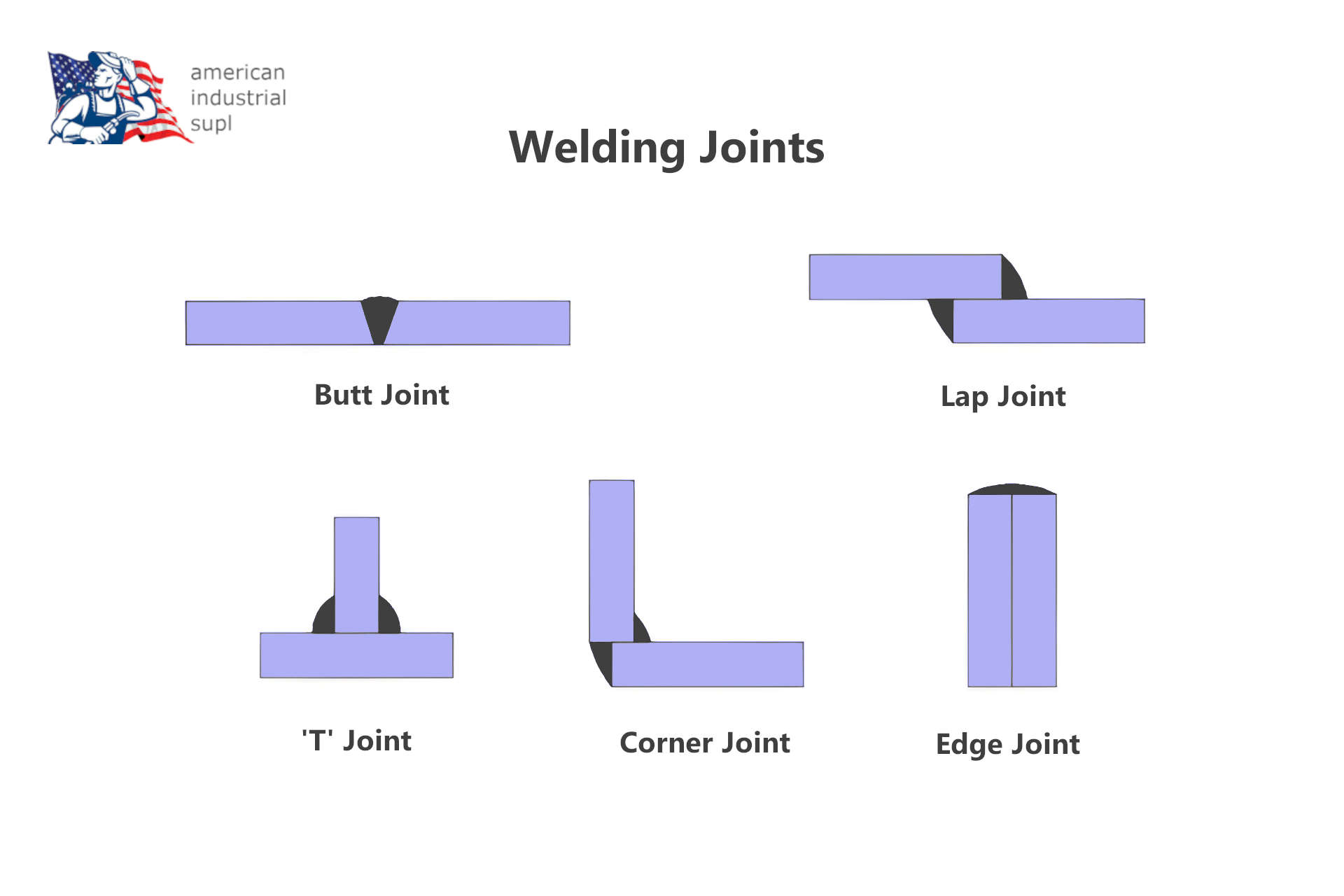

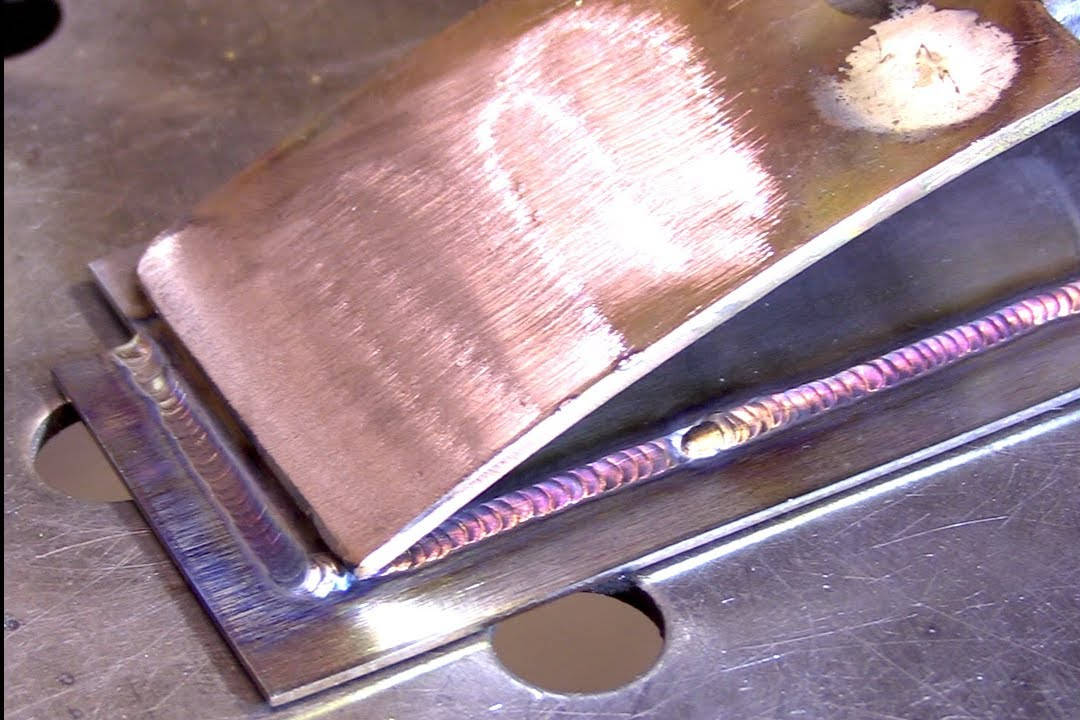

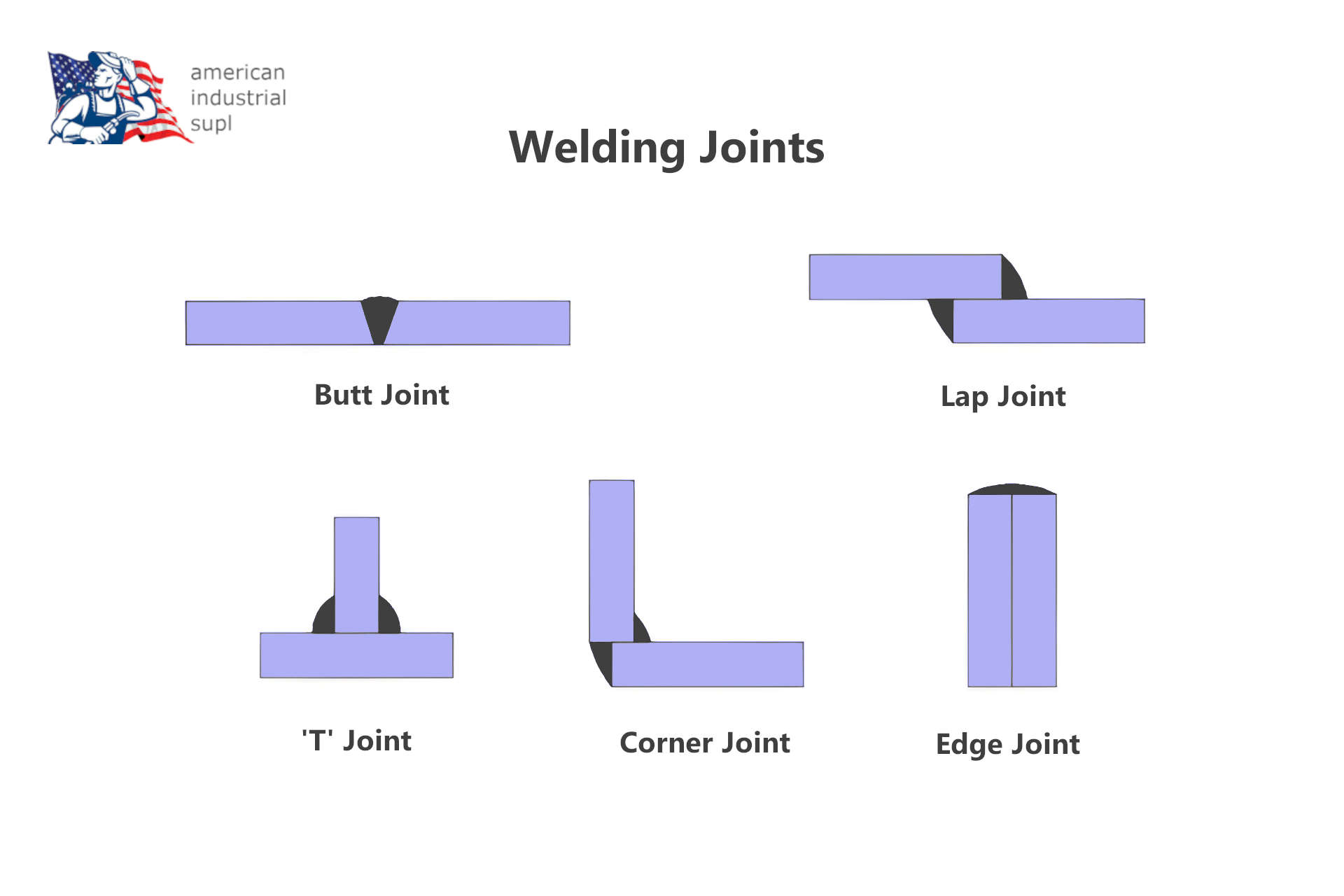

What Are the Different Types of Joints in Welding?

When it comes to welding, one of the most critical aspects to understand is the different types of joints in welding that are utilized to create strong and durable welded structures. The joint is where two pieces of metal are fused together through the welding process. Selecting and properly preparing the right type of joint…

-

What is the Difference Between AC and DC Welding?

AC and DC welding are two different types of welding currents that affect how the arc is created and maintained between the electrode and the workpiece. AC stands for alternating current, which changes its direction periodically. DC stands for direct current, which flows in one direction only. The choice of welding current can have a…

-

What Are the Differences Between MIG Welding versus Flux- Cored Arc Welding

Flux-Core and MIG welding are two of the most commonly used welding techniques. Flux-Core welding uses a continuously-fed consumable electrode, which is shielded by a flux compound to protect the weld area from atmospheric contamination. MIG welding, on the other hand, uses a continuously-fed consumable wire electrode and a shielding gas to protect the weld…

-

What is the Right Shielding Gas for Welding Aluminum?

What is the Right Shielding Gas for Welding Aluminum? Controlling aluminium welds entails a variety of elements, including selecting the proper filler metal and shielding gas composition, as well as ensuring your power supply is properly set up to ensure quality welds as the end result. Inert Shielding Gases When deciding what is the right…

-

What is the Best Shielding Gas for Welding Stainless Steel?

What is the best shielding gas for welding stainless steel? Welding stainless steel may be accomplished in a variety of methods, each requiring a particular shielding gas. We will examine the most popular stainless steel welding methods and determine which gas types is best for each. Properties of Stainless Steel Stainless steel has been used…

Welding Equipment

-

Lincoln Electric FC90 Flux Core Wire Feed Welder: Hands on Review

After reading glowing reviews from welders using Lincoln Electric FC90 flux core wire feed welder for small jobs and repairs, we decided to take a closer look At the Lincoln FC90 and see if it was the right flux core welder for small workshops or home use. We were eager to see how this this…

-

Everlast SM200-mts Spoolgun | Review

Everlast spool gun is universal that can be fitted to any welder that uses Euro Quick-connect connectors. It is reasonably lightweight gun, weighing in at 8.6lbs and takes standard 1lbs spools (maximum roll diameter 4″) with feed wire sizes 0.023-0.040″. The gun is quick to load and has a drive roller and tension adjustment. Feeding…

-

Miller MIG/TIG Welder Combo

The Miller Syncrowave 210 TIG/MIG is one of those welders that seems to check practically all the boxes. As the title suggests it is almost the complete welder. An inverter welder with both AC and DC settings, it allows you to weld either as MIG, TIG or stick, with the additional benefit of being able…

-

Tig Welding Gloves

The glove choice for many people who TIG weld is a glove with a goatskin exterior. This is because it helps the easy management for the precision required by the welder when using the TIG torch. This is because the TIG glove is designed for the welder to easily pick up his welding rod and…

-

Best Welding Gloves

Choosing the correct welding glove / welding gauntlets can make a big difference both to the quality of the weld that you produce and the safty of the welder. Not all welding gloves are equal. You need different welding gloves for different types of welding. In this article we will look at choose the correct…

-

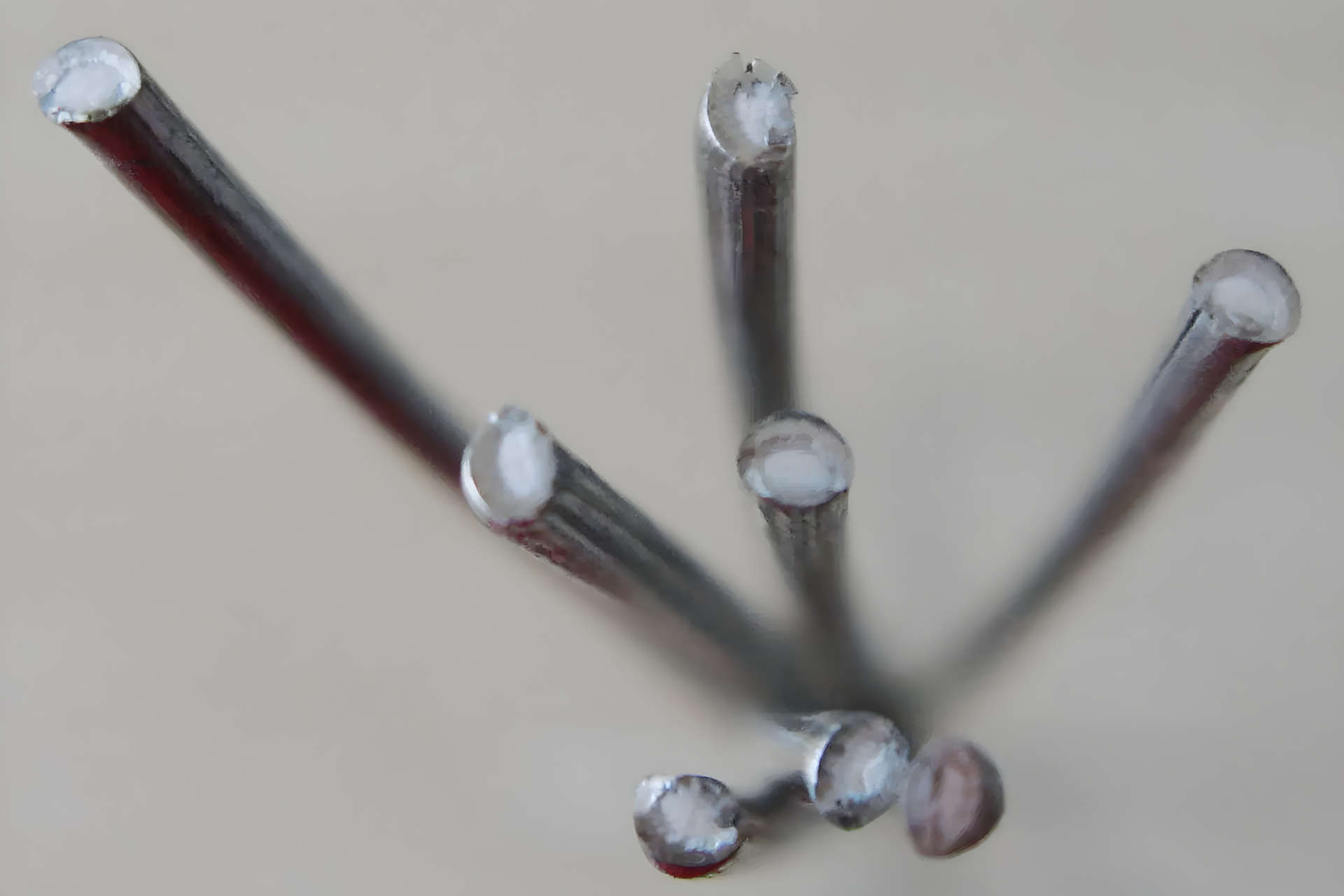

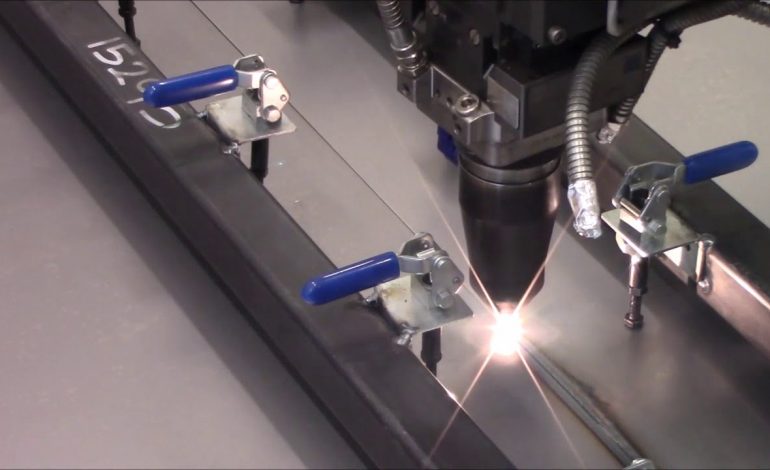

Arc Machines New M217 Orbital Welder

Arc Machines (AMI). pioneers in the field of orbital welding have just released their newest orbital welding system, the M217. This welder follows on from their previous models, the M107 and M207 with the later and the M205 being deprecated. This new workhorse is offered as a compact unit creating ease of portability for on-site…

Laser Welding

-

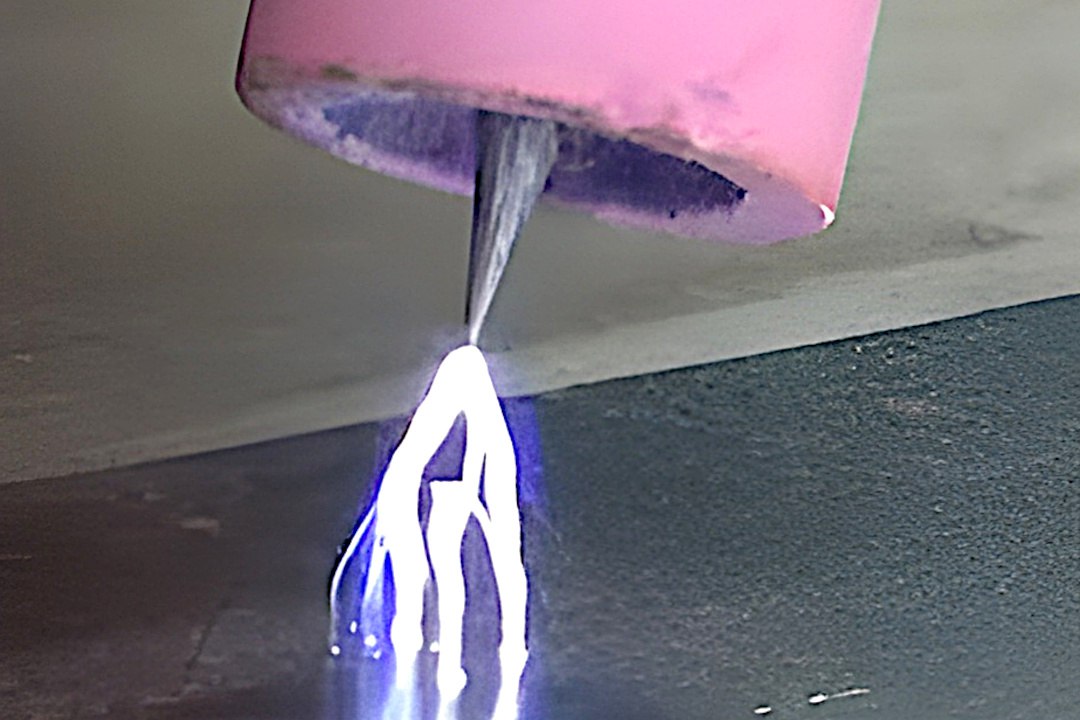

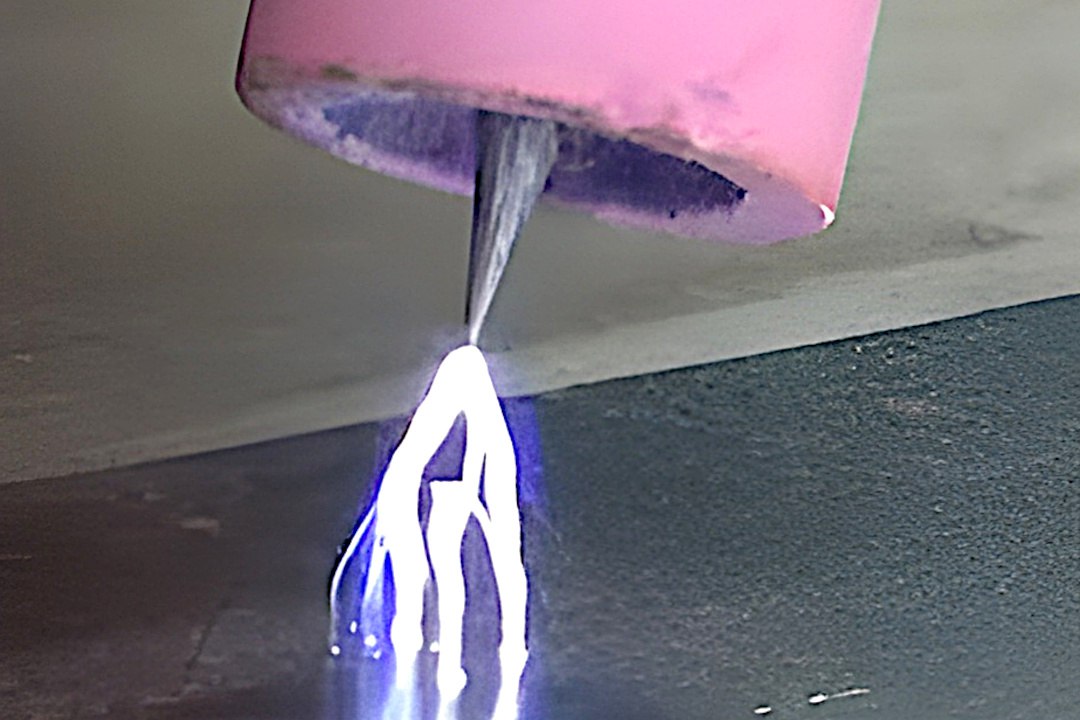

Laser Welding: What You Need To Know

Laser welding, or more commonly refereed to as laser beam welding is an industrial welding process for joining metal components together at high speed. It usually produces small and very narrow weld seams and the process has low thermal distortion. This type of welding lends itself well to large scale production lines were the ability…

Welding Courses and Tutorials

-

The Secret to Welding Steel to Aluminum

Not all metals are easy to weld together. Some metals have different physical and chemical properties that make them incompatible for welding. One of the most challenging combinations of metals to weld is steel and aluminum. Steel and aluminum are very different metals with respect to their melting points, thermal conductivities, expansion coefficients, and solubilities….

-

What Are the Different Types of Joints in Welding?

When it comes to welding, one of the most critical aspects to understand is the different types of joints in welding that are utilized to create strong and durable welded structures. The joint is where two pieces of metal are fused together through the welding process. Selecting and properly preparing the right type of joint…

-

What is the Difference Between AC and DC Welding?

AC and DC welding are two different types of welding currents that affect how the arc is created and maintained between the electrode and the workpiece. AC stands for alternating current, which changes its direction periodically. DC stands for direct current, which flows in one direction only. The choice of welding current can have a…

-

Flux Core Welding Polarity Demystified: The Key to Perfect Welds Revealed!

Flux core welding utilizes consumable electrode wires filled with flux to provide shielding for the weld pool. Polarity, or the direction of current flow, is an important but often overlooked parameter when flux core welding. The selection of direct current electrode positive (DCEP), sometimes referred to as reverse polarity welding, direct current electrode negative (DCEN),…

-

Weld Spatter: How to Eliminate or Minimize the Problem

Preventing and mitigating weld spatter (splatter) is essential for ensuring a successful welding process. Not only can weld spatter impact the appearance of the finished product, but it can also create safety hazards and result in added cleanup time. Weld spatter can damage surrounding equipment, contaminate surfaces, and even pose a risk of injury to…

-

Moving Your Welding Career Forward

Welding is a profession into which a lot of people fall into by accident. Obviously there are many welders out there who decided, probably early in their working life, that they wanted to be a welder or involved in the welding industry. However, there are probably more who got into welding by accident or through…